Electrical Classification of Areas Containing Combustible Dusts

Combustible dust is utilized in a number of facilities in different capacities, such as in food processing, plastics handling/production, wood, and metal manufacturing facilities. However, combustible dusts can ignite and result in flash fires and/or explosions if the quantity of dust suspended in air is above the minimum explosible concentration (MEC) and a competent ignition source is present. As a result, assessment and mitigation of hazards associated with combustible dusts is paramount in minimizing the likelihood of combustible dust incidents within the facilities, which can result in injuries and fatalities and costly property damage. Dust hazard analyses (DHAs), required by NFPA 652 Standard on the Fundamentals of Combustible Dusts, serve to identify potential hazards associated with combustible dusts and recommend strategies to prevent ignition and subsequent explosion of the dusts.

As part of the DHA, hazardous area classification requirements are used to determine the classification of the electrical equipment necessary for the areas in which combustible dusts may be present. NFPA 499 Recommended Practice for the Classification of Combustible Dusts and of Hazardous (Classified) Locations for Electrical Installations in Chemical Process Areas outlines a systematic approach for classifying hazardous locations based on the requirements set forth in NFPA 70 National Electrical Code. These locations are categorized based on the concentrations of combustible dusts which may be present and the likelihood of dust presence within the area.

Class II locations are areas where combustible dusts are or may be present in quantities sufficient to produce explosive or ignitable mixtures.[1] Class II locations are further divided into two divisions, Division 1 and 2. Division 1 locations are those where hazardous concentrations of combustible dusts exist under normal operating conditions, or where such concentrations may exist frequently due to maintenance or equipment failure.[2] Division 2 locations are those where hazardous concentrations of combustible dusts are not normally present but may occur under abnormal conditions, such as accidental rupture of equipment.[3]

Dusts are further grouped based on their properties (E, F, and G), which influence the classification requirements of electrical equipment in proximity to the dusts. Table 1 provides an outline of the definitions for the groups of dust.

| Table 1: Dust Types by Group | |

| Dust Group | Dust Type |

| Group E | Metal Dusts (Conductive and Explosive) |

| Group F | Carbonaceous Dusts (Carbon Black, Coal, or Coke Dusts) |

| Group G | Dusts Not Included in Groups E or F (Grain Dusts, Flour, and Other Combustible Dusts) |

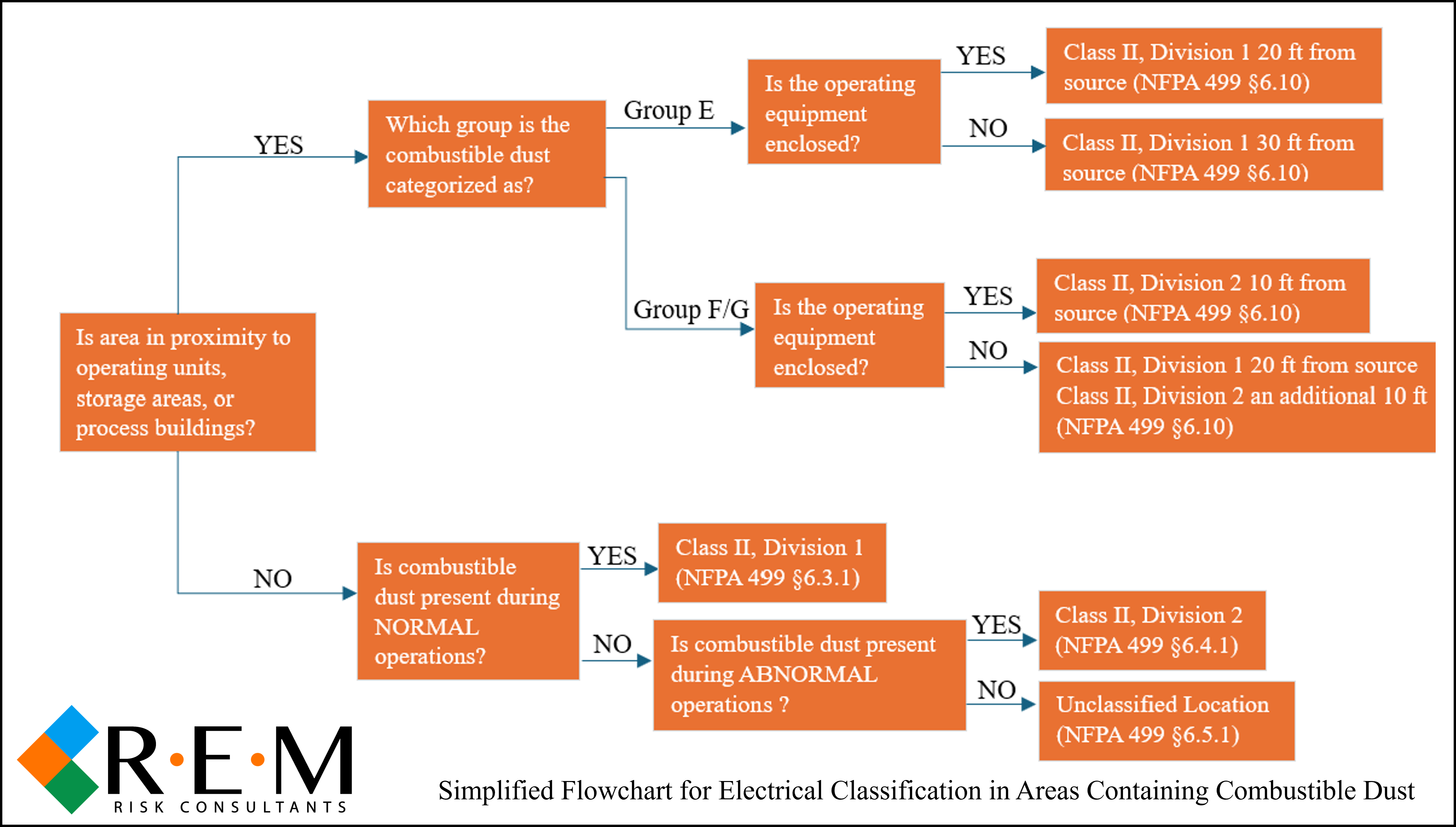

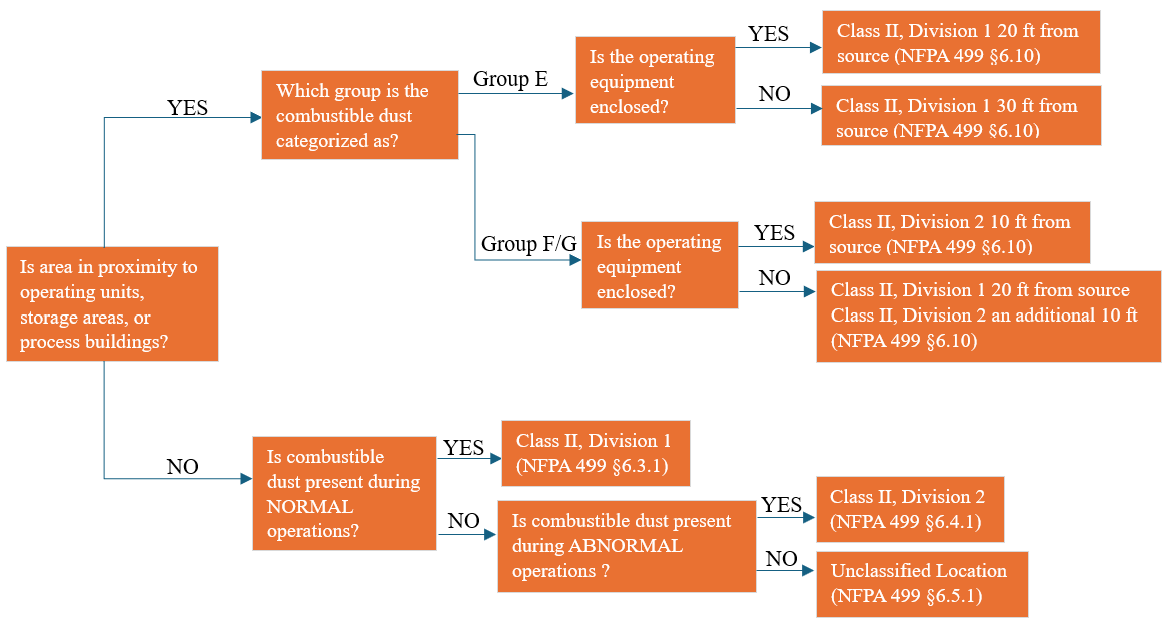

For areas surrounding operating units, storage areas, and process buildings, NFPA 499 contains classification diagrams based on the dust group of the combustible dust. In addition to the dust group, factors that influence the extent of the classified location include the specific particle density of the dust, whether the process equipment is open or enclosed, and whether the area in which the dust is located is walled off from other areas. To facilitate consistent assessments of combustible dust hazards within the facilities, REM Risk Consultants has developed a flowchart to determine the extent of classification necessary based on the properties of the combustible dust, equipment (such as whether the equipment is fully enclosed), and facility (such as whether the area is walled off). A simplified example of this flowchart is shown in Figure 1.

Figure 1. REM’s Simplified Flowchart for Electrical Classification in Areas Containing Combustible Dust

The flowchart serves as a useful tool when developing the DHAs, as it ensures that consistent electrical classification guidelines are provided within each DHA produced for areas of facilities in which combustible dusts may be present. Electrical classification guideline consistency ensures that the DHAs are effective tools for both the identification of potential dust hazards as well as the recommendation of strategies to prevent combustible dust ignitions and explosions within facilities.

[1] 2023 NFPA 70 §500.5(C) Classifications of Locations.

[2] 2024 NFPA 499 §6.3.1 Class II, Division 1 Classified Locations.

[3] 2024 NFPA 499 §6.4.1 Class II, Division 2 Classified Locations.

REM Risk Consultants assists clients with all aspects of Business Continuity and Resiliency – from process safety and fire protection solutions to occupational health and organizational risk management. Please contact REM to discuss your combustible dust needs and the full flowchart we use when performing DHAs.